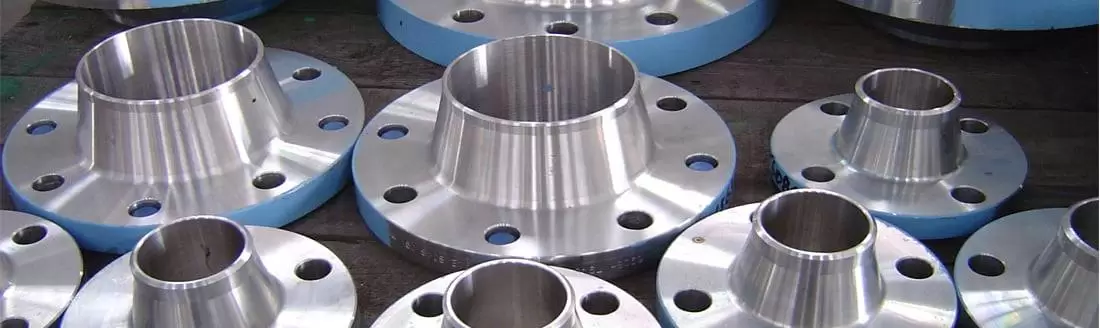

FLANGES

PRIME BUILD ENGINEERING manufactures flanges at its own facilities in Texas and Mexico.

Flanges are manufactured using three main techniques: casting, cutting from rolled plate material, or forging. We produce them by utilizing plate/cut technology with the highest quality

Below is the comparison of the technologies:

Our flange manufacturing process begins with top-quality raw materials, which undergo a rigorous testing and approval process prior to purchase by the manufacturer. The resulting Mill Test Report (MTR) declares the chemical and physical properties and verifies that the materials meet the minimum requirements set forth by the applicable standards.

The raw materials selection depends on a client application. We offer in the flange production:

Mild/Carbon Steel

Stainless Steel

Ductile Iron

Aluminum

The flange finish—the roughness or smoothness as well as type of serrations—is completed after the flange is cast, forged, or cut. Flange finish requirements vary based on the selected standard and application. Flange finish options include continuous and concentric serrated, smooth, mill or rolled, and machined finish, and/or electroplating.